Building Chemistry with Custom PVC Compound Solutions

At Deceuninck, your compounding edge starts with our compounding capacity and a half-century experience of expertise in processing polymers and developing applications for industry. Deceuninck offers three classes of custom PVC compound solutions to meet the exacting manufacturing requirements for processing, heat stability, weatherability, color consistency and application.

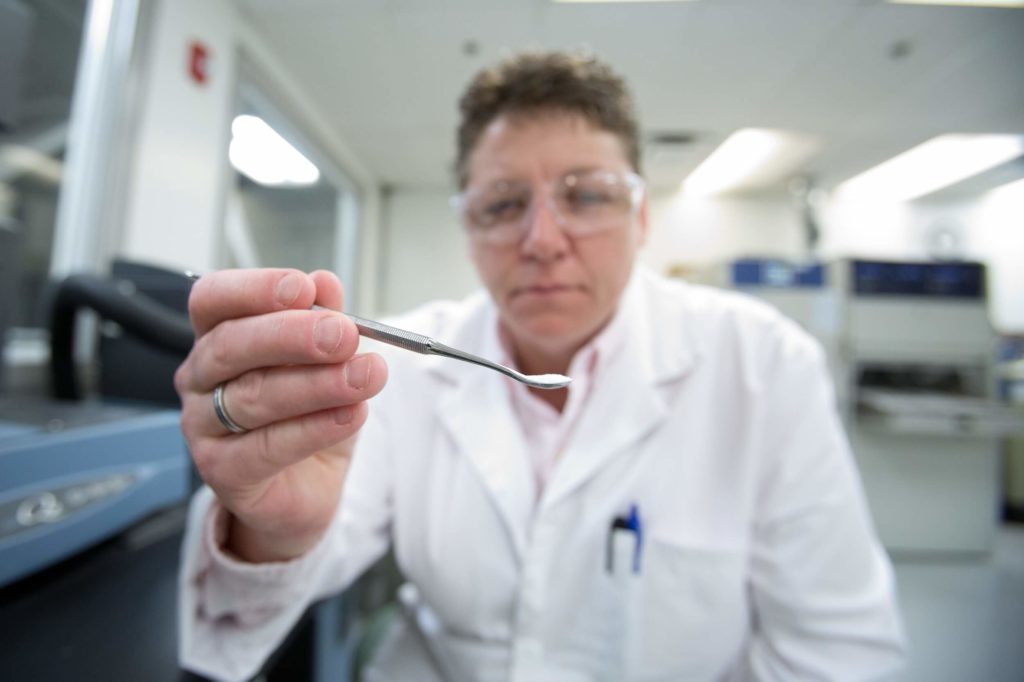

Our experts. Your advantage.

Formulation integrity, compound precision, extrusion process accuracy.

Based on industry-leading and proprietary PVC material technologies for profile extrusion, injection molding and blow molding applications, Deceuninck customizes the design of compounded materials to meet each customer’s exacting requirements

Our expertise is compounded by working with some of the world’s most innovative manufacturers to develop and engineer materials and processes which create true value, manufacturing efficiencies, and lasting product attributes.

Quality Assurance is also a major component of our Precision Polymer Compounding Solutions. Rigorous testing protocols provide on-going quality control operations, and certificate of assurance documentation is available for each delivery.

Performance meets precision with custom PVC compound solutions

MASTERY Customer Blends

For proprietary high performance.

Applications: Custom-designed proprietary materials; High performance characteristics including heat distortion, heat gain, impact, UV; Composites.

ARTISTRY Premium Blends

For superior exterior performance.

Applications: Window and door materials; Decking and railing cap stocks; Siding cap stocks.

EFFICIENCY Performance Blends

For rugged everyday performance.

Applications: General service PVC material; Siding, window and decking substrates; Customer defined and intermediate compounds.